Komet instruments are your choice for fast and efficient cutting of crowns and bridges from all current metal alloys, titanium and ceramics.

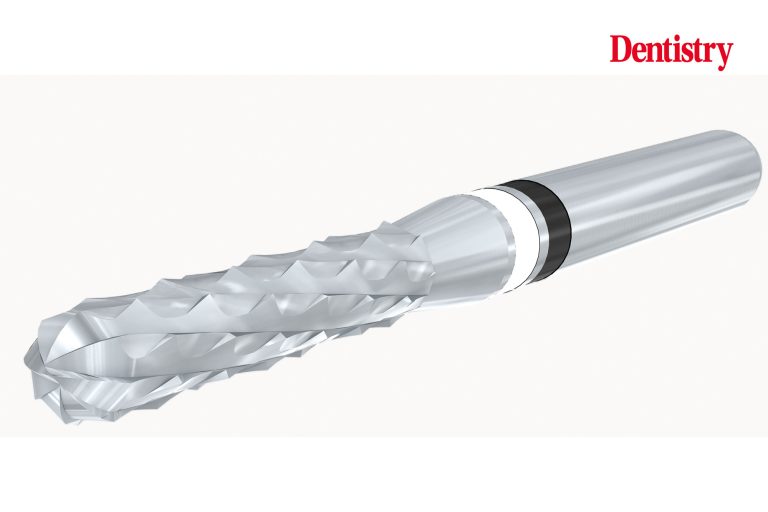

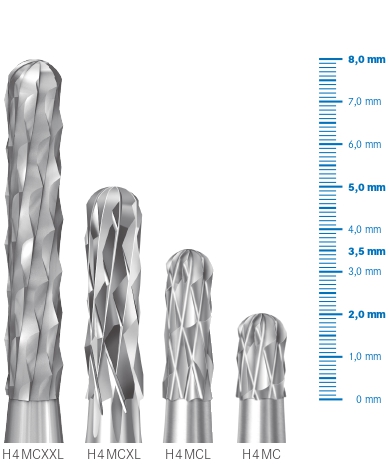

H4MC – the rim cutter for metals and ceramics.

Designed to cut all commonly used metal alloys, titanium and low-fusing ceramic veneers.

Due to the special D dentition, the H4MC facilitates fast and efficient cutting of crowns and bridges from conventional metal alloys.

Large chip spaces allow quick chip removal and prevent clogging, especially when cutting soft alloys with gold content. H4MC is equally suitable for ceramic veneers.

An additional feature is the transverse blade that allows easy penetration into the material to be cut. The pyramid-shaped blade design prevents blade breakage and guarantees increased stability and high breakage resistance, thus ensuring a smooth operation with little vibration.

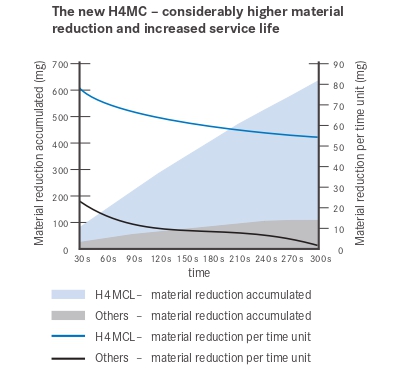

Compared to all other crown cutters on the market, including copycats made by the competition, the H4MC (workpiece available in various lengths, H4MC – H4MCXXL) has a consistently higher material reduction rate.

These cutters prove particularly effective in the case of difficult-to-cut non-precious metal alloys such as Dentitan. The instruments can be used on both the micromotor and the turbine.

Indications:

- H4MC can be identified by its white and black rings (white for ceramic, black for metal)

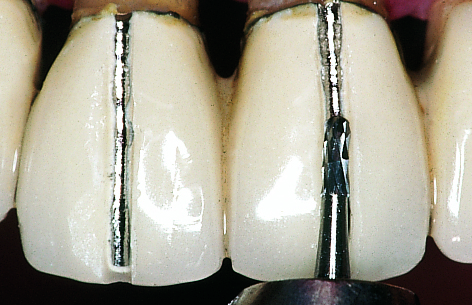

- Crowns should be cut in several steps, ie the process should be done at intervals so that only a small area is cut at a time

- Ceramic veneers must be cut with the tungsten carbide crown cutter H4MCL.314.012 (image 1)

- Metal crowns must be cut with crown cutter H4MCL.314.012 (image 2).

Recommendations for use:

- Optimum speed: 160,000 rpm on the micromotor

- In the case of materials that tend to “jump”, (e.g. some non-precious metal alloys) we recommend using the turbine, applying a low contact pressure

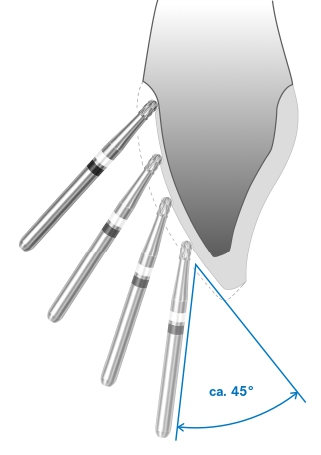

- In order to fully utilize the capacity of the working part of the instrument during the cutting phase, we recommend applying the instrument at an angle of approximately 45 degrees to the crown

- Always ensure that sufficient coolant is applied (at least 50 ml/min)

- Do not exceed the maximum contact pressure of 2N.

These crown cutters are not suitable for cutting all-ceramic crowns and bridge frames made of extremely hard ceramics, such as zirconium oxide ceramics. For this, we recommend the crown cutter 4ZR.314.012 specially designed for zirconium oxide.

4ZR and 4ZRS – rim cutters for all-ceramic rims

We recommend the 4ZR and 4ZRS crown cutters for separating all-ceramic crowns, including zirconia. Thanks to their special bond incorporating the diamond grains, the life and cutting performance of these crown cutters are clearly superior to those of traditional diamond instruments.

When removing self-adhesive all-ceramic restorations, the instrument should be able to cut not only the axial separation slits, but also along the incisal edge and, in the posterior region, the buccal surface.

To remove the restoration, it must be expanded until it opens. This can be done with a lever or Planert crown expansion forceps (DP 788R Aesculap Dental, Tuttlingen, Germany).

Both crown cutters are applied at an angle of 45 degrees and are used at an optimum speed of 160,000 rpm. Work with low contact pressure and cool the spot during the separation process.

Advantages:

- Special bond

- Excellent substance removal

- Long lifespan.

For more information visit www.kometdental.co.uk/crown-cutters.