Milos Ljubicic discusses SprintRay’s 3D printing workflow for dental restorations, an innovative method for creating inlays, inlays and overlays.

Introduction

Dentistry has undergone a remarkable transformation with the advent of 3D printing technology. Gone are the days when patients had to endure multiple visits for reconstructive procedures. With advanced 3D printing solutions, dental professionals can now provide patients with a more efficient and convenient experience.

This article explores the use of 3D printing technology to create inlays, inlays and overlays in a single visit. This is a revolutionary approach to the way we treat dental restorations.

The patient’s dilemma

Imagine a patient walking into a dental office seeking to replace old fillings and repair cavities. Traditionally, such restorations required multiple appointments, numerous impressions and temporary restorations before the final one was ready. This process is not only time-consuming but also frustrating for the patient. However, with the innovative capabilities of 3D printing, this patient experience can be drastically improved.

The solution

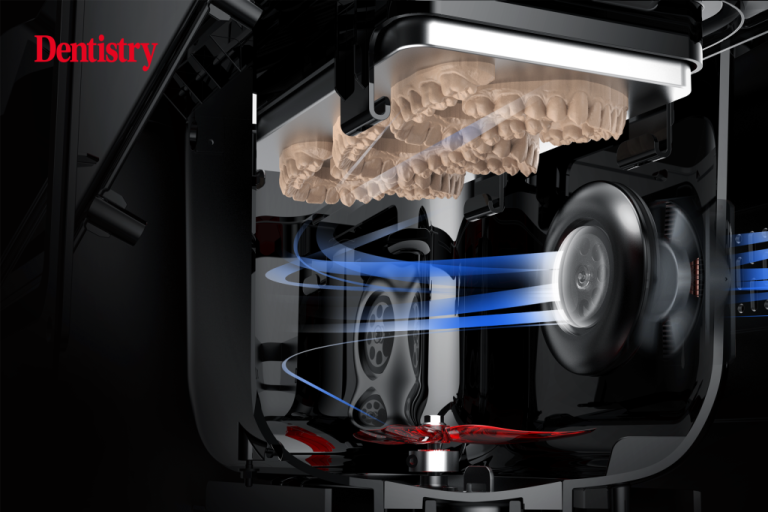

There is a good range of 3D printers specifically designed for dental applications, e.g. by SprintRay. These printers use advanced materials and high resolution printing technology. Therefore, dental professionals can create accurate and durable dental restorations in a fraction of the time compared to traditional methods.

Create hybrid restorations in one visit

With the help of SprintRay’s 3D printers and their unique Crown Kit, dental professionals can now create inlays, inlays and veneers using the latest hybrid resin materials (SprintRay Crown) in a single visit. The process is relatively simple and time-efficient, sparing patients the hassle of multiple appointments.

That’s how it works

1. Digital scanning

The patient’s teeth are digitally scanned using an intraoral scanner (Medit i700 Wireless). This 3D scan creates a highly accurate virtual model of the patient’s dentures, eliminating the need for messy traditional impressions.

2. CAD drawing

The virtual model is imported into the computer-aided design software (MeditClinicCAD). Here, the dental professional custom designs the inlay, inlay or veneer to precisely fit the patient’s tooth.

3. 3D printing

Once the design is complete, the digital file is sent to the SprintRayPro 95S 3D printer. Using the selected hybrid resin material (SprintRayCrown), the printer begins the additive manufacturing process, layer by layer, until the restoration is complete.

4. Wash and dry

After about 20 minutes of printing, thanks to the Crown Kit that speeds up the process, the dental professional carefully removes the restoration from the printer. The printed restorations are then placed in the SprintRay Wash and Dry unit. Here, they are thoroughly washed with isopropyl alcohol to remove any excess resin and ensure optimal cleanliness.

5. Final adjustments

The dental professional then makes the necessary final adjustments and polishing. This guarantees a perfect fit and natural appearance of the restoration. Once adjustments are complete, the restorations are transferred to the SprintRayProCure2 unit for the final curing process.

6. Light curing

The ProCure2 unit uses advanced light curing technology to fully cure the resin, enhancing the strength and durability of the restoration. This step is vital to ensure that the restorations are ready for immediate use as soon as they come out of the curing unit.

7. Welding

With the printing, washing, curing and cementing procedures completed in a single visit, the patient can walk out of the dental office with the new, fully functional and aesthetically pleasing restoration, thanks to the remarkable capabilities of SprintRay’s 3D printing technology.

Restorations are cemented securely into place using G-CEM ONE universal dual-cure self-adhesive cement, designed to provide a strong and durable bond to indirect restorations. This ensures a long-lasting and reliable result for dental health and patient satisfaction.

The advantages for patients and dentists

Incorporating SprintRay’s 3D printing technology into dental practices offers several advantages:

- Time efficient: patients can complete their restorations in a single visit, saving them valuable time and reducing the number of appointments required

- Improved precision: 3D printing ensures a high level of precision and a perfect fit to each patient’s unique dental anatomy, leading to improved restoration longevity and functionality

- Improved esthetics: the hybrid materials used in 3D printing closely mimic the appearance of natural teeth, providing patients with esthetically pleasing and discreet restorations

- Streamlined workflow: dental professionals can streamline their workflow, reducing chair time and increasing patient throughput, ultimately benefiting both the practice and patients.

conclusion

3D printing technology has revolutionized the field of dentistry, offering patients an improved and efficient experience when it comes to restorative dental procedures.

Using innovative solutions such as SprintRay’s Crown workflow, dental professionals can now provide high-quality, precise and esthetically pleasing inlays, inlays and veneers in a single visit, ushering in a new era of ease and excellence in dental restorations.

For more information, visit sprintray.com.